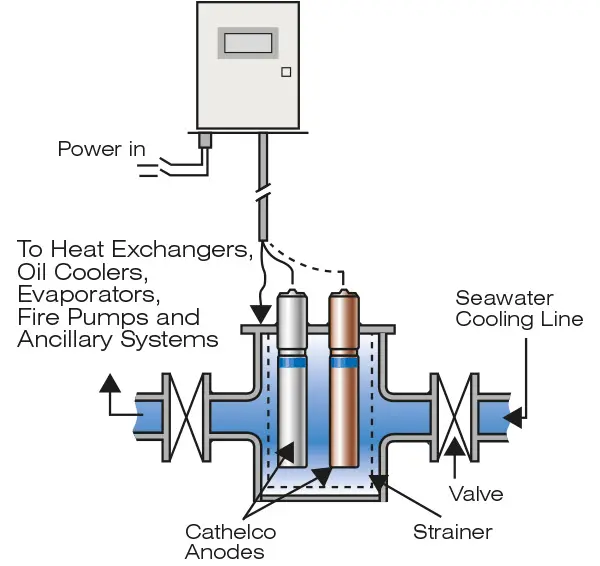

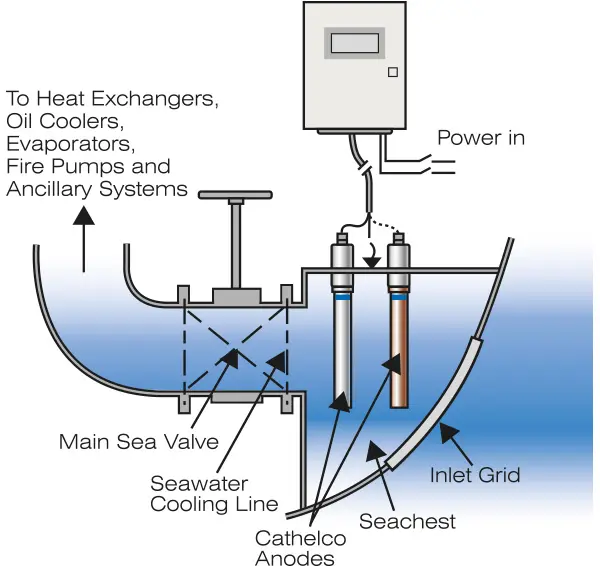

Our Cathelco marine growth prevention systems (MGPSs), also known as antifouling systems) usually consist of pairs of copper and aluminum anodes, mounted in sea chests or strainers and connected to a control panel. Where cupro-nickel pipework is used on board, a ferrous anode is used instead of the aluminium anode.

In operation, the copper anode produces ions which are carried by the flow of seawater, creating an environment where barnacles and mussels will not settle or multiply.

By introducing copper ions in very small concentrations, around two parts per billion, the system interrupts the settlement sequence of mussel and barnacle larvae. Instead of adhering to the surface of sea chests, strainers, and pipework, the larvae pass harmlessly through the cooling water system to the discharge point.

Without antifouling protection, pipes can become encrusted with organisms, leading to a blockage which reduces the efficiency of the seawater cooling system.

Our Cathelco marine growth prevention systems (MGPSs) for seawater pipework are easy and economical to install, and they can be found on more than 50,000 ships worldwide. Designed to eliminate blockages caused by barnacle and mussel growth in seawater cooling lines, the systems are available for vessels of every size including mini systems for luxury yachts.

New EU Biocide Regluations

As of September 2015, owners and operators of vessels sailing in European waters must ensure that their marine growth prevention systems comply with the EU Biocides Regulation 528/2012. Cathelco is one of the few companies listed under Article 95, the official register of approved active substance suppliers recognized by the European Chemicals Agency (ECHA). This makes installing genuine Cathelco equipment and anodes a safe way to ensure regulatory compliance.

Failure to use equipment from an authorized supplier may affect a ship’s Green Passport, leading to financial penalties and even imprisonment.

Key Features of the Cathelco Marine Growth Prevention Systems

The action of the copper ions is assisted by aluminum hydroxide that is created by the aluminum anodes flocculating the released copper from the copper anodes. This highly gelatinous copper-aluminum hydroxide floc is carried throughout the system and tends to spread into the slow-moving areas close to the pipe surfaces, where marine larvae are most likely to settle. As a result, the larvae instead pass directly to discharge.

At the same time, a cupro-aluminum film builds up on the internal surfaces of the pipes to suppress corrosion. In this way the system has a dual action, protecting seawater pipework against both biofouling and corrosion.

When a system is installed during vessel construction anodes are generally fitted in the sea chests using special sleeves or flange mountings. If a system needs to be retrofitted prior to scheduled drydocking on the other hand, the anodes can be mounted in the seawater strainers. This simplifies the replacement process when anode renewal becomes necessary.

In special cases where the Cathelco system is installed to supersede existing chemical-based antifouling equipment, the anodes can be mounted in treatment (electrolysis) tanks in order to reduce installation costs by utilizing existing pipework.

Options and features of the Cathelco MGPS

Corrosion can be accelerated in two ways. The presence of biofouling on a metal surface leads to a decreased oxygen concentration below the layer of fouling. This area becomes anodic when exposed to oxygenated seawater, resulting in pitting corrosion under the fouling. Another cause of corrosion is bacteria – for example, sulfate-reducing and iron bacteria are well known examples of microorganisms whose biological activity or metabolic by-products can cause corrosion. These bacteria live in areas with a low oxygen concentration, for instance under a layer of aerobic fouling organisms, or in de-aerated water such as that found in oil storage tanks and well flood water. Efficient fouling control results in a reduction in pitting and crevice corrosion.

Most Cathelco marine growth prevention systems have a dual action, eliminating biofouling and suppressing corrosion. Where steel pipework is in use, the corrosion suppression anodes are made of aluminum, whereas cupro-nickel pipework is protected using ferrous anodes. When these anodes are fitted, corrosion rates are significantly reduced, resulting in a longer lifetime for the pipework and other equipment connected to the seawater system.

Antifouling electrolysis tanks

Deck-mounted electrolysis tanks are designed with pipework that distributes the dosed seawater to pumps or sea chests. Copper ions are carried throughout the seawater pipework system, eliminating blockages caused by barnacles and mussels. Control mechanisms can be linked to inlet valves or pumps to automatically regulate the dosage between sea chests that are in or out of use. The units are specifically designed for each application and supplied as skid-mounted turnkey modules ready for installation.